Solutions

Touch interfaces for modern automotive

One Technology – Three Solutions

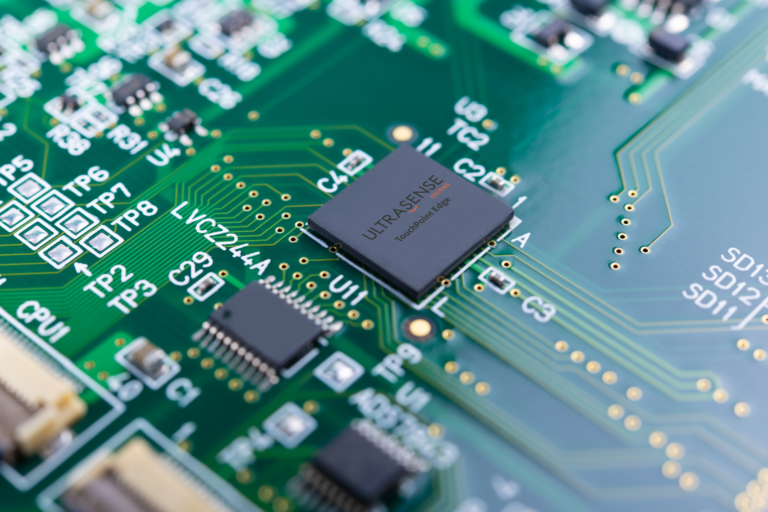

UltraSense TouchPoint HMI Controllers

Fully integrated multi-mode touch sensing, lighting control, and algorithm processing in a single System on a Chip

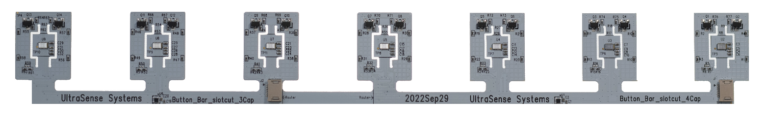

UltraSense InPlane Sensing Solutions

Driver-vehicle touch interfaces integrating multi-mode sensing, illumination, and haptics with a single printed circuit board (PCB)

UltraSense Solid-State Interface Module

Plug-and-play SSI module integrating multi-mode sensing, customizable lighting, and controls for OEMs and tier-suppliers

What Makes UltraSense Technology Unique?

Superior multi-mode sensing accuracy, control, and performance

Highly Localized & Accurate

Precise sensing of tap, multi-tap, swipe and hold gestures, even with gloves

Works with Any Material

Senses through any thickness of metal, glass, wood, plastic, leather or stone

Reliable & Resilient

Piezoelectric force-sensing is immune to stresses of temperature, aging, and wear

Eliminates False Triggers

Fuses ultrasound, force, and capacitive sensors to register only intended touch

Hidden-Until-Lit Capability

Adjustable lighting and haptics for modern, minimalist designs

Easy Calibration & Customization

Self-tunes with AI / ML algorithms, with tuning software for customization

Holistic Standalone Operation

System on a Chip (SoC) integrates sensor, transducer, and ASIC in a monolithic die

Proven Technology & Expertise

25+ patents with deep experience in the design and delivery of sensor solutions